FCI Series

Purpose

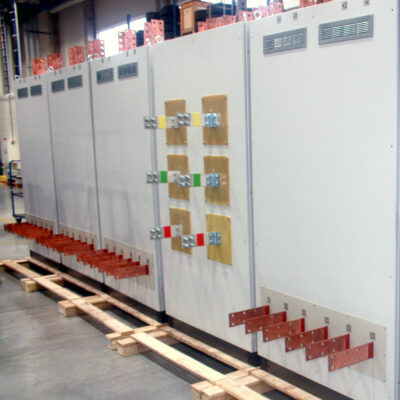

The FCI series frequency converter for induction heating is designed for electrothermal systems and can be used either as a standalone device in the melting, heating or hardening process or as an integrated device and a part of technological systems. The main difference from TFC is in the wider range of adjustment, smaller size and the ability to work at higher frequencies.

FCI series generators are designed to surpass thyristor inverters in certain operational characteristics:

- withstanding repeated long-term intermittent working mode

- automatically adjust working frequency

- smaller dimensions, mass, and water consumption

Main advantages

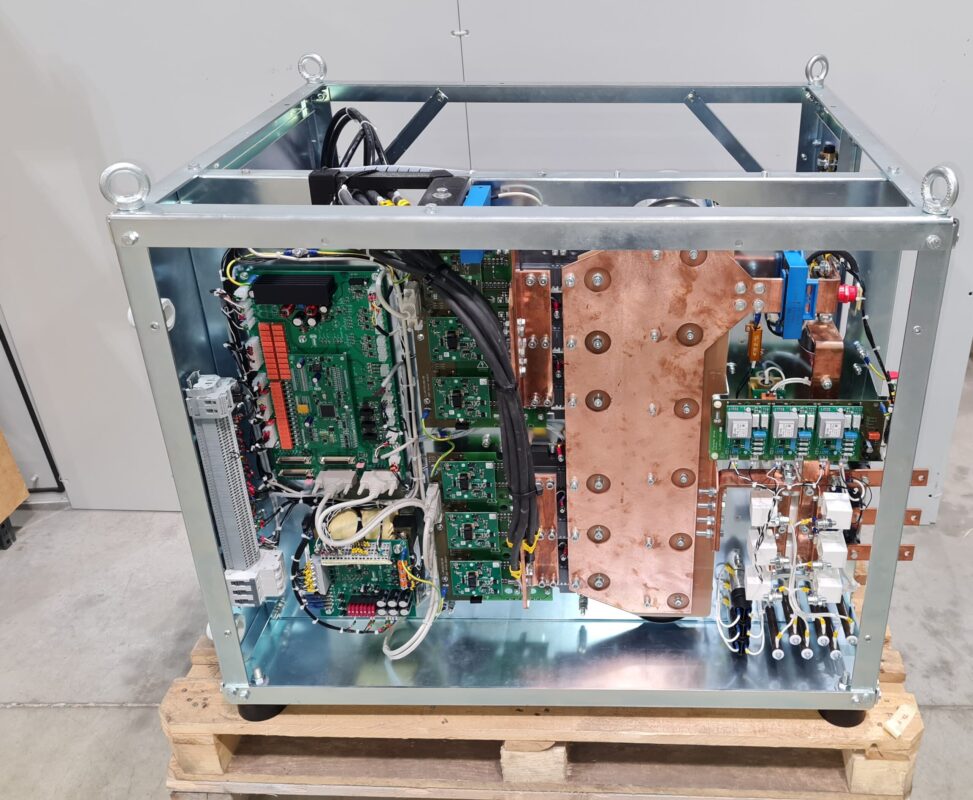

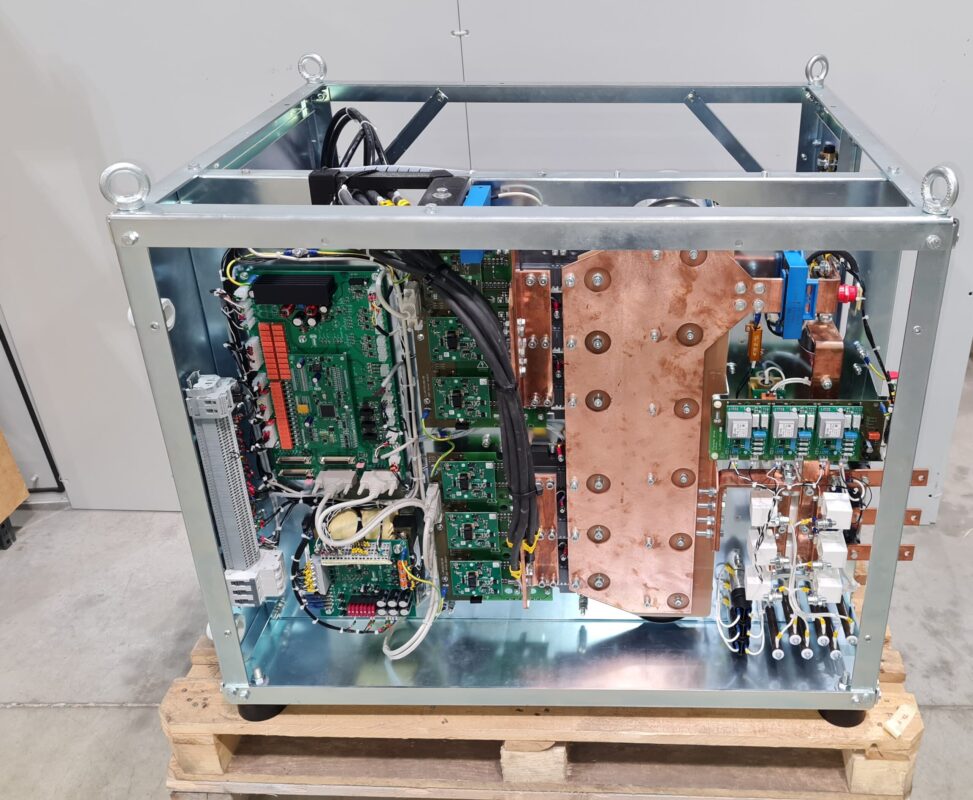

Using the IGBT modules as inverter power elements allowed simplifying the generator’s power circuit:

- significantly reduces the size of the reactor

- eliminates the starter block

This allowed reducing the size and weight of the generator. Using a microprocessor control system has significantly improved the usability of the generator.

Unlike a thyristor inverter, a transistor inverter can operate at cos=1 which increases its efficiency.

| Main characteristics of standard units | |||||||

| FCI-60 | FCI-100 | FCI-175 | FCI-225 | FCI-300 | FCI-400 | FCI-600 | |

| Nominalc output power, kW | 60 | 100 | 175 | 225 | 300 | 400 | 600 |

| Nominal output frequency, kHz | 0.04−16.0 | ||||||

| Nominal output voltage, V | 400-1200 | ||||||

| Nominal supply voltage, V | 3×380 / 3х415 / 3×550 | ||||||

| Nominal water flow rate, m3/hour | 0.6 | 0.8 | 1,5 | 1,75 | 2,00 | 2,5 | 3,5 |

| Overall dimensions, mm | |||||||

| Length | 600 | 800 | 800 | 800 | 800 | 800 | 1200 |

| Height | 1500 | 1500 | 2000 | 2000 | 2000 | 1800 | 2100 |

| Depth | 600 | 600 | 800 | 800 | 800 | 800 | 800 |

| Weight, kg | 160 | 200 | 250 | 300 | 400 | 600 | 720 |

| Customized parameters are possible according to the customer requirements | |||||||